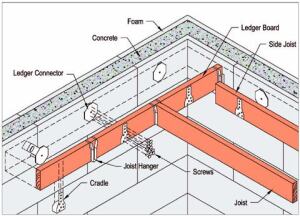

Many methods are used to attach wood frame floors to insulating concrete form (ICF) exterior walls. The most popular ones involve connecting a wooden ledger board to the walls at floor height. Then floor joists are connected to the ledgers with conventional joist hangers. The end joists running along the side walls also must be connected to those walls.

A popular method of attaching the ledger boards to the walls is with the ICF “ledger connector.” This steel connector is embedded in the concrete when the wall is cast. Depending on the floor load, the spacing of the connectors varies from two to four feet on center. The connectors are installed at floor height. If the ICFs will compress during the pour, the connectors are installed higher to compensate. Since most compressible forms settle about 1/16 inch for each course of block, the connectors are installed about 3/8" high to achieve an 8-foot high floor. (With most ICF blocks, an 8-foot elevation is made with six courses of block.)

The modern ledger connector has two legs that are embedded in the concrete. The contractor holds the connector in position against the wall, taps it to create indents where the legs contact the foam, and cuts along the indents to create slots for the legs. The connector has an optional hole for screwing to the ICF ties to secure it. This requires that connectors be positioned over a tie. If the connectors are not screwed to ties, it is advisable to secure them in some other way to prevent them from shifting during the pour.

Consolidating the concrete around the legs is important so that the legs are fully embedded. After the concrete has cured, workers mark the design height of the floor on the walls and lift the ledger into position. One steel “cradle” goes around the ledger board at each connector location. The workers run screws through each cradle, driving them through the ledger board and into the face of the connector. Eight self-drilling screws are required at each connector. The cradles and screws are supplied with the connectors, and substitute products should not be used.

It is best to plan the positions of the ledger connectors so that they do not coincide with the positions of the joists. Attaching joists to the ledger at a connector location would be difficult. Joists may, however, be attached to the ledger at almost any point between the connectors.

Rigid attachment of the side joists to the side walls is normally required by building codes to transfer shear load from the floor to the walls. In addition, connecting the side joists to the walls reduces the flex of the floor. The attachment can be made with additional ledger connectors pre-installed along the side walls.

There are other methods of attaching ledger boards to ICF walls, attaching side joists to ICF walls, and of connecting floors to ICF walls without the use of ledgers. These will be covered in later issues.

—Pieter VanderWerf works for Building Works, Inc., a consulting firm that helps companies introduce new construction products. He may be contacted at www.buildingworks.com